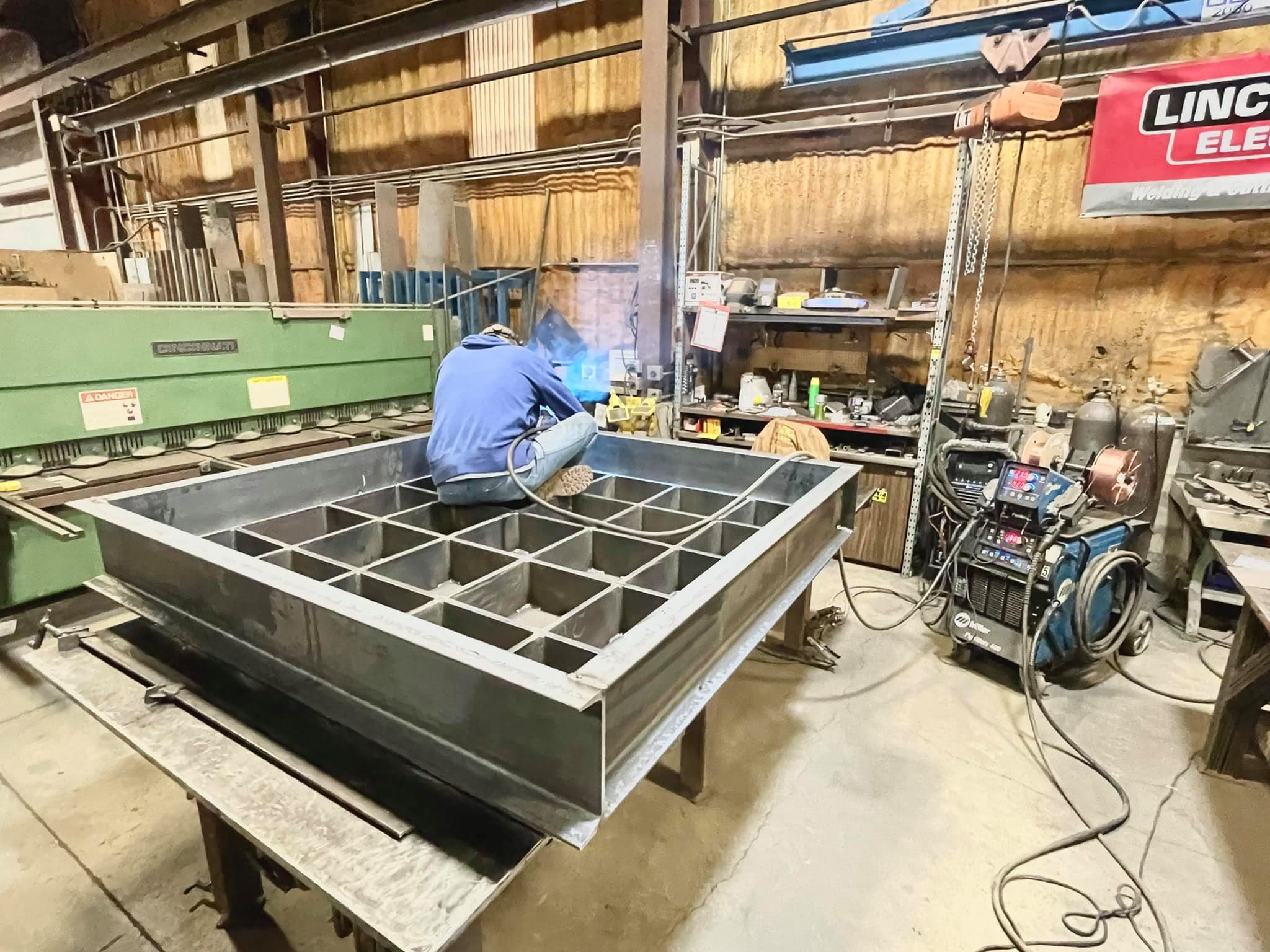

Custom Fabrication Shop

With experienced welders, fabricators, and machinists in house, we are able to help our customers solve their steel design, build, and repair needs. We strive for quick turnaround and our steel service center allows us to pull material from our own inventory to get fabrication jobs done quicker.

Fabrication services include:

Custom design work using the latest AutoCAD & SOLID-WORKS

Shearing:

- Mild steel up to 1/2" x 144"

- 3 total plate shears (Niagara, Cincinnati, & Standard)

Bending:

- 90 Ton x 8ft Cincinnati Press brake - 5 axis backguage - auto - crowning ( NEW 2023 )

- 350 ton x 14' Cincinnati press brake - 5 axis backgauge - auto-crowning

- 60 ton x 8' hydraulic press brake

- New WILA/Wilson tooling - we can make custom tooling for you job!

Sawing:

- FIVE Marvel saws capable of cutting 18" x 21" segments

- Do-ALL Auto Feed +Miter saw - capable of cutting 12" x12" segments/bundles

Rolling:

- Roundo R5- up 2-1/2" square or round pipe

- Eagle Pyramid Roll w/ UHMW Dies

- Erconlina pipe bender

- Wysong 1/4" x 8" Plate Rolls

- DAVI 5/8" x 6' 6" CNC Plate Rolls ( NEW 2024)

- Small 1/4" x 4" FOUR Roll plate roll + Slip Roll

Cutting:

- Messer Plasma 8' x 20' down draft table - Hypertherm XPR 300 with maximum cut 2" plate

- Oxy-cutting up to 8"

Abrasive Waterjet Cutting:

- Wardjet E-1530

- 5' x 10' cutting area

- Cut up to 10" thick - any material

- Accepts DXF. and DWG. files

Welding:

- 7 welding bays with 5 ton overhead cranes.

- Welding of all types of material ( Carbon, Aluminum, Stainless, Inconel, & Exotics)

- 15+ Mig and Tig welding machines

- 50KVA TECNA rocker arm spot welder

- Keystone Fastener Stud Welder

- Welding in conjunction with the American Welding Society ( All welders certified to AWS D1.1 + other specialty CERTs)

Misc Equipment:

- 90 and 60 ton Whitney punches

- 7 Drill presses

- Plate Bevelers

- Flexarm Hydraulic Tapping Arm - GH-24 (1/4 to 1" capacity)

- Hand held plasma cutter

- Radial arm drill

- 50 ton hydraulic press

- Manual sheet metal break

- Vibratory finishing ( stainless and aluminum)

- Paint booth 14' x 12' x 10' and Powder Coating ( See Powder Coating page for more details)

- Portable Sand Blasting

- FULL SERVICE CRANE TRUCK w/ Lincoln Ranger 305 for onsite welding

In-house Machine Shop

- Machining is performed on precision lathes and milling equipment to exact specification

- Three Vertical Mills with auto feeds

- Two manual lathes

- Surface grinding

- Precise band saw

Delivery:

- 2021 International - 26ft Flatbed

- 2019 Chevy Cab over - 16ft Flatbed

- 2021 Ford F-250 - Shop Runner

- Chevy Pickup- Install/field work truck

- NEW JLG Lift and Skid Steer available for shop/field work